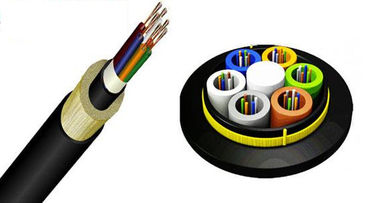

OPGW optical cable, also known as optical fiber composite overhead ground wire, is to place optical fiber in the ground wire of overhead high-voltage transmission line to form an optical fiber communication network on the transmission line. This structure has dual functions of ground wire and communication. Generally, It is called OPGW optical cable.

Because the OPGW optical cable is wrapped with metal wires, the optical cable is more reliable, stable and firm. Since the overhead ground wire and the optical cable are integrated, it not only shortens the construction period but also saves construction costs compared with other optical cables.

In addition, if the OPGW made of aluminum-clad steel wire or aluminum alloy wire is used, it is equivalent to erecting a good conductor overhead ground wire, which can receive and reduce the latent power supply current of the transmission line, reduce the power frequency overvoltage, and improve the communication line between the power line and the communication line. Interference and dangerous effects and other benefits. Because the optical fiber has the characteristics of anti-electromagnetic interference and light weight, it can be installed on the top of the transmission line tower without considering the best hanging position and electromagnetic corrosion. Therefore, OPGW has notable features such as high reliability, superior mechanical properties, and low cost. This technique is especially suitable and economical when laying new or replacing existing ground wires.

Classification of OPGW

1. Aluminum tube type

The optical fiber unit of the aluminum tube type is to use the core of the ordinary optical cable and add an aluminum tube to the outer layer to form the optical fiber unit of the early OPGW optical cable. At present, the optical cable of this structure has been eliminated.

2. Aluminum skeleton type

Skeleton type The optical fiber unit structure is formed by directly twisting the coated (heat-resistant material coated) optical fiber in the aluminum skeleton slot + aluminum tube. The optical fiber unit is basically composed of aluminum, and the high temperature generated under the impact of short-circuit current makes the internal fiber core always have safety hazards.

3. Steel pipe type

The stainless steel tube type stainless steel tube is used as the loose tube of the optical fiber unit, which makes full use of the physical properties of the stainless steel material, that is, the stainless steel material has the characteristics of poor conductivity and corrosion resistance. It has become the mainstream product of OPGW optical cable.

Applications

OPGW optical cables are mainly used on 500KV, 220KV, and 110KV voltage level lines. Due to line power outages, safety and other factors, they are mostly used on new lines.

The applicable characteristics of OPGW are:

(1) Lines with high voltage exceeding 110kv have large spans (generally above 250M);

(2) It is easy to maintain, and it is easy to solve the problem of line crossing, and its mechanical characteristics can meet the large span of lines;

(3) The outer layer of OPGW is metal armor, which has no effect on high-voltage electric corrosion and degradation;

(4) OPGW must be powered off during construction, and the loss of power outage is relatively large, so OPGW should be used in new high-voltage lines above 110kv;

(5) Among the performance indicators of OPGW, the greater the short-circuit current, the more it is necessary to use good conductors for armoring, which reduces the tensile strength accordingly. In the case of a certain tensile strength, the only way to increase the short-circuit current capacity is to increase the metal cross-sectional area , resulting in an increase in cable diameter and cable weight, which poses a safety issue for the strength of the line tower.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!