All-dielectric self-supporting (ADSS) cable is a type of optical fiber cable that is strong enough to support itself between structures without using conductive metal elements. It is used by Electrical utility companies as a communications medium, installed along existing overhead transmission lines and often sharing the same support structures as the electrical conductors.

ADSS is an alternative to OPGW and OPAC with lower installation costs. Designed to be strong enough to install up to 700 meters of cable between support towers, ADSS cables are lightweight and small in diameter, reducing the weight of the cables and the loads placed on the tower structure by wind and ice.

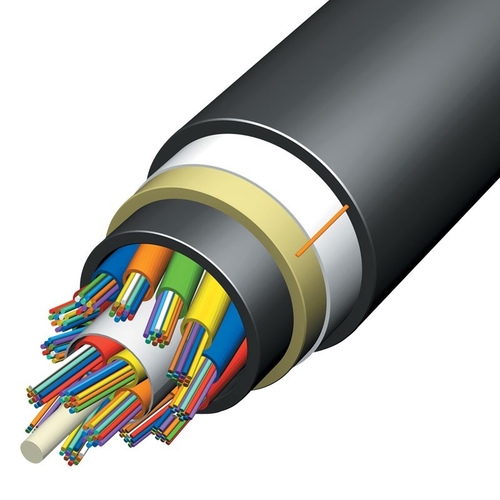

The cable is designed so that the inner glass optical fibers are supported with little or no strain to maintain low optical loss over the life of the cable. The cable is jacketed to prevent moisture from degrading the fiber optics. The jacket also protects the polymer strength elements from the sun's UV rays.

Using single-mode fibers and light wavelengths of either 1310 or 1550 nanometres, circuits up to 100 km long are possible without repeaters. A single cable can carry as many as 864 fibers.

Construction Details

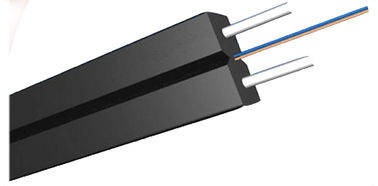

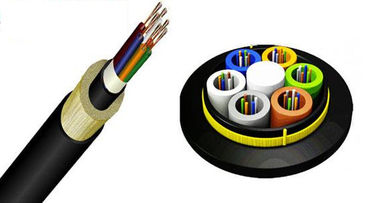

No metal wires are used in an ADSS cable. Optical fibers are either supported in loose buffer tubes, or arranged in a ribbon configuration. To prevent strain on the fibers, most types provide the fibers with excess slack length compared to the length of the supporting member.

For longer spans, the most common design gets its strength from aramid fiber yarns, which are coated to prevent water wicking. The aramid yarn strength member surrounds a core made up of multiple buffer tubes, each containing multiple fibers, all surrounding a plastic core. The outer sheath provides protection from water and sunlight. Another version consists of a large central tube containing multiple flat, thin structures called fiber ribbons; these consists of 6 or 12 fibers laminated between layers of a tape-like material.

Another type of design uses four glass-reinforced plastic strength member strands, and loose buffer tubes cabled into an assembly and protected by a jacket.

Accessories and installation

Fittings used with ADSS cable may be tension type, used at dead-ends where the cable terminates or changes direction, or may be suspension type, only holding the weight of a span with tension transmitted through the next span of cable. Reinforcing rods are used at dead-ends and may sometimes be used on either side of a suspension support. Wind-induced aeolian vibration may be a factor on longer spans since ADSS cables have light weight, relatively high tension, and little self-damping. Anti-vibration dampers may be installed on each span near the support points if needed. Accessories must not be clamped directly to the cable but instead over reinforcing rods, to protect the cable from electrical and mechanical damage. Termination boxes are used to enclose and protect splices between the ADSS cable and "inside plant" cable runs.

ADSS cable can be installed using live-line methods on an energized transmission line. Fiber cables are generally supported on the lower cross-arms of the tower, which provides good clearance to the ground. When the fibers are installed in the middle of a tower, the fiber cable is unlikely to hit energized conductors. Lower weights and forces are used for installation, compared with metallic cables, so lighter equipment can be used.

Installation technique is similar to installing overhead conductors, with care taken to prevent excessively tight bending of the cable, and adjustment of the sag of individual spans as for metallic cables.

Conclusion

ADSS cable is ideal for installation in distribution as well as transmission environments. Since the ADSS cables provide an optimal solution for a broader combination of fiber counts and span lengths, more and more aerial cabling system designers tend to adopt them for telecommunications, like power utilities, telcos, and private network groups. Combining convenience

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!