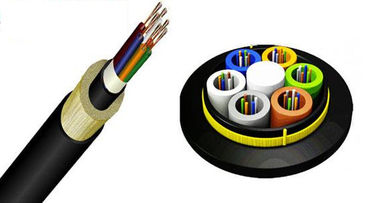

ADSS All-dielectric Self Support Outdoor Aerial Fiber Optic Cable 2-144 core

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines under 110kV, PE outer sheath is applied. FOR power lines equal to or over 110kV, AT outer sheath is applied. The dedicate design of aramid quantity and stranding process can satisfy the demand on various spans.

Features

1.All-dielectrical self-supporting aerial fiber optic cable, no metal material in the structure

2.Large number of fiber cores, light weight, can be installed with power line, saving resources

3.Adopt high tensile strength aramid material to withstand strong tension and prevent cockles and gunshots

4.Small thermal expansion, the varation of the arc of the cable line is small when the temperature changes greatly

5.Double layer of aramid yarn as strength member, meet the harsh enviroment such as the high-altitudes salt lake area or the line with a span of more than 800 meters

6.Three layer sheath, PE/AT as outer jacket

Specifications

| Cable fiber count |

/ |

2~30 |

32~60 |

62~72 |

| Structure |

/ |

1+5 |

1+5 |

1+6 |

| Fiber style |

/ |

G.652D |

| Central strength member |

material |

mm |

FRP |

| Diameter (average) |

1.5 |

1.5 |

2.1 |

| Loose Tube |

Material |

mm |

PBT |

| Diameter (average) |

1.8 |

2.1 |

2.1 |

| Thickness(average) |

0.32 |

0.35 |

0.35 |

| Max fiber/loose tube |

6 |

12 |

12 |

| Tubes color |

Full color identification |

| Fiber excess length |

% |

0.7~0.8 |

| Water resistance |

Material |

/ |

Cable jelly |

| Inner sehath |

material |

mm |

MDPE |

| Inner sheath |

0.9mm |

| Non-metallic strengthen components |

Material |

/ |

Aramid Yarn |

| Outer sheath |

material |

mm |

MDPE |

| Outer sheath |

1.8mm |

| Cable diameter(average) |

mm |

10.9 |

11.5 |

12.1 |

| Cable weight (Approximate) |

kg/km |

95 |

110 |

120 |

| Cable Sectional area |

mm2 |

93.31 |

103.87 |

114.99 |

| Attenuation coefficient(Max) |

1310nm |

dB/km |

0.35 |

| 1550nm |

0.21 |

| Rated Tensile Strength(RTS) |

kn |

6 |

| Max allowed tension( MAT) |

kn |

2.5 |

| Annual average operating tension (EDS) |

kn |

3.2 |

| Young's modulus |

kn/mm2 |

7.8 |

| Coefficient of thermal expansion |

10-6/℃ |

9 |

| Crush resistance |

Long term |

N/100mm |

1100 |

| Short term |

2200 |

| Permission Bent Radius |

static |

mm |

15 of OD |

| dynamic |

20 of OD |

| Temperature |

When laying |

℃ |

-20~+60 |

| Storage and transportation |

-40~+70 |

| runing |

-40~+70 |

| Scope of application |

Suitable for voltage level under 110kV, wind speed below 25m/s, icing 5mm |

| Cable Marks |

Company Name ADSS-××B1-PE-100M DL/T 788-2001 ××××M Year

(Or at customer’s request)

|

Note : This datasheet can only be a reference, but not a supplement to the contract. Please contact the sales for the details.

Structure and Product Pictures

Packing & Shipping

Cable is supplied in lengths as specified in PI or as requirement. Each length will be shipped on a separate iron-wooden drum. The minimum barrel diameter of the drum will not be less than 30 times the cable diameter.

The cable ends will be sealed with plastic protection caps to prevent water penetration. The ends will be easily accessible for testing. A final inspection test report with attenuation performance data for each fiber is attached inside the drum.

Our company

Exhibition

Our certificates

Quality and Safety

We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Our products have passed RoHS, ISO9001 and TLC certifications.

Our Principles

Full customer satisfaction

Commitment to high-quality service

Long-term cooperation and profits for each other

WE LOOK FORWARD TO HEARING FROM YOU!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!